When working with vacuum systems, high-precision laboratory setups, or even certain industrial applications, you might come across 1.33 CF flange tapped bolts. But what exactly are they, and why are they important?

If you’ve ever struggled to find the right bolts for your ConFlat (CF) flanges, you’re in the right place. In this blog post, we’ll break it all down in simple, easy-to-understand language—no confusing jargon!

What Are 1.33 CF Flange Tapped Bolts?

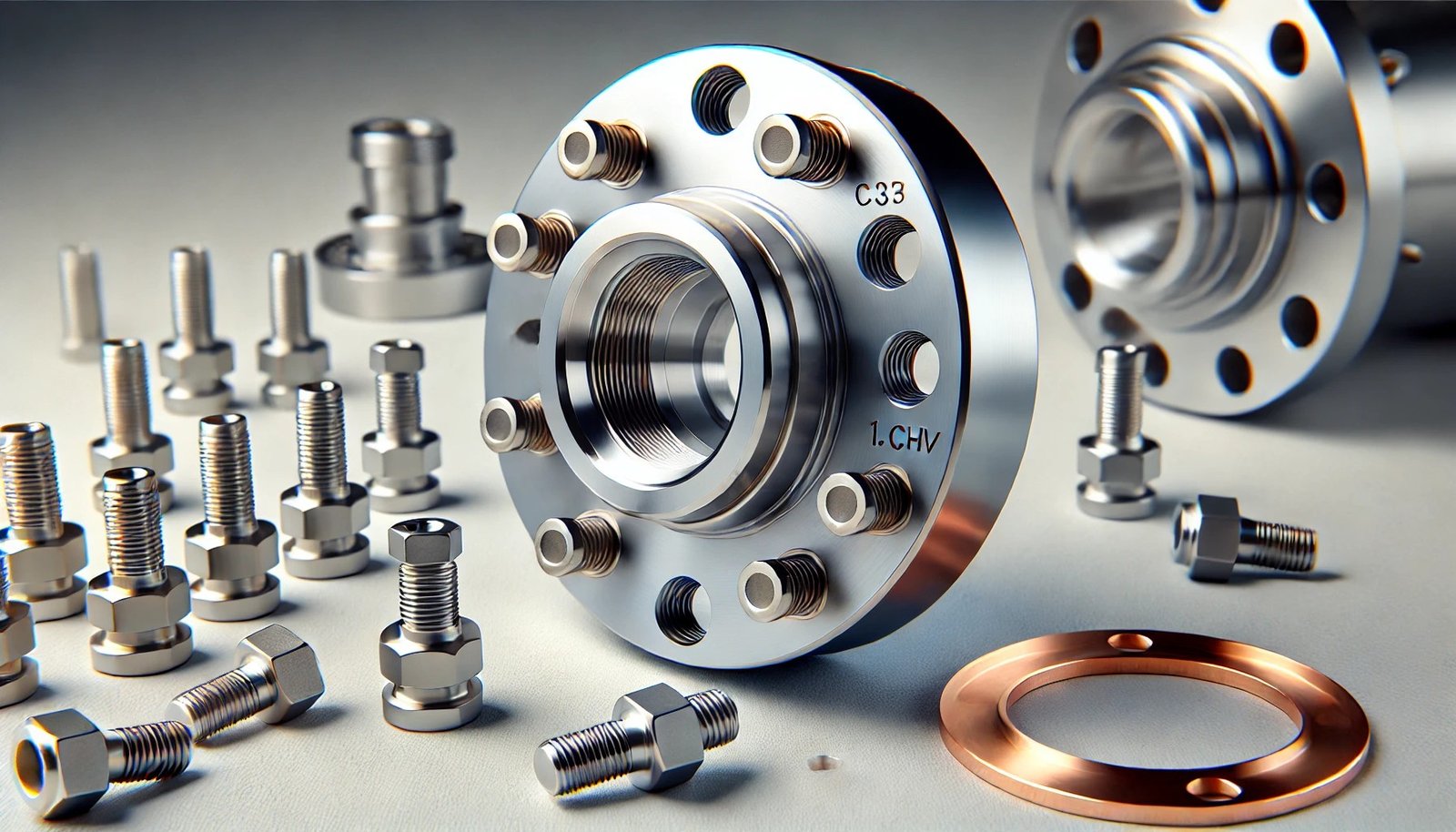

Before we dive into the bolts, let’s quickly talk about CF flanges. These flanges are commonly used in ultra-high vacuum (UHV) systems because they create airtight, leak-free seals. The 1.33 CF flange is one of the smallest in the CF series, and it’s typically used for small vacuum components.

Now, tapped bolts are special because they screw directly into the flange. This means you don’t need separate nuts—making assembly simpler and neater.

Key Features of 1.33 CF Flange Tapped Bolts:

- Threaded into the flange – No need for separate nuts.

- Used with 1.33 CF flanges – The smallest CF flange size.

- Made from stainless steel – Resistant to corrosion and ideal for vacuum applications.

- Provides secure sealing – Essential for ultra-high vacuum environments.

Why Are These Bolts Important?

If you’re working with vacuum chambers, scientific instruments, or industrial vacuum systems, you know how important airtight connections are. A tiny leak can ruin an experiment, slow down production, or cause safety risks. That’s where 1.33 CF flange tapped bolts come in—they help create and maintain a secure seal without unnecessary parts.

How They Make Your Life Easier:

- Less hardware to manage – No need to keep track of extra nuts.

- Easier installation – Just screw them directly into the flange.

- More compact design – Ideal for tight spaces.

- Better alignment – Reduces chances of misalignment during assembly.

Where Are 1.33 CF Flange Tapped Bolts Used?

You might be wondering: “Do I even need these bolts?” Let’s see where they’re commonly used.

Common Applications:

- Scientific Research Labs – Used in vacuum chambers for physics and chemistry experiments.

- Semiconductor Industry – Essential for maintaining ultra-clean environments.

- Medical & Pharmaceutical Equipment – Found in sterilized, vacuum-sealed environments.

- Space and Aerospace Engineering – Used in vacuum testing for spacecraft components.

- Industrial Manufacturing – Helps in processes that require controlled atmospheres.

If you’re working in any of these fields, you’ve probably seen these bolts—or you’ll need them soon!

Choosing the Right 1.33 CF Flange Tapped Bolts

Not all bolts are created equal. When buying 1.33 CF flange tapped bolts, here are some things to consider:

1. Material

- 304 Stainless Steel – Common choice, corrosion-resistant, affordable.

- 316 Stainless Steel – More resistant to harsh chemicals, better for extreme environments.

- Titanium – Lightweight and strong but more expensive.

2. Thread Size

- Standard #6-32 threads are the most common for 1.33 CF flanges.

- Always check your flange specifications before buying.

3. Length

- Make sure the bolt is long enough to secure your components but not too long, or it won’t fit properly.

- Typical lengths range from ¼ inch to ½ inch.

4. Surface Finish

- A smooth, polished finish is ideal for vacuum applications because rough surfaces can trap contaminants.

How to Install 1.33 CF Flange Tapped Bolts Correctly

Using these bolts is pretty straightforward, but a few small mistakes can cause leaks. Follow these steps for a perfect seal:

Step 1: Clean Everything

Before installation, make sure your bolts, flange, and gasket are completely clean. Even tiny dust particles can cause vacuum leaks.

Step 2: Position the Gasket

Place a copper gasket between the flanges. This is what creates the vacuum seal.

Step 3: Insert the Bolts

Since the flange is already tapped, you can directly screw in the bolts without nuts. Start by loosely placing them in.

Step 4: Tighten Evenly

Use a torque wrench and tighten the bolts in a crisscross pattern. This ensures even pressure on the gasket, preventing leaks.

Step 5: Double-Check for Leaks

Once everything is in place, perform a vacuum test to make sure there are no leaks.

Pro Tip: Never over-tighten! Too much pressure can crush the gasket and ruin the seal.

Common Mistakes to Avoid

Even experienced engineers make mistakes. Here are some common errors to watch out for:

❌ Using dirty or scratched gaskets – Always use new, clean copper gaskets.

❌ Over-tightening the bolts – Can damage the gasket and create leaks.

❌ Skipping the torque wrench – Uneven tightening can lead to poor seals.

❌ Using the wrong bolt length – Too short? Won’t hold. Too long? Won’t fit.

Where to Buy 1.33 CF Flange Tapped Bolts

You can find these bolts at:

- Industrial supply stores

- Vacuum component manufacturers

- Online marketplaces (Amazon, McMaster-Carr, eBay, etc.)

Before purchasing, double-check the specs to ensure they match your flange requirements.

Conclusion

1.33 CF flange tapped bolts might seem like small, simple components, but they play a huge role in maintaining vacuum integrity. By choosing the right material, thread size, and length, and following proper installation steps, you can prevent leaks and ensure reliable performance.

If you work with vacuum systems, lab equipment, or industrial machinery, having the right bolts can make all the difference!

FAQs

1. What is the difference between tapped and through-hole CF flanges?

- A tapped CF flange has threads for bolts, so you don’t need nuts.

- A through-hole CF flange requires nuts on the back to secure the bolts.

2. Can I reuse CF flange bolts?

Yes, but only if they are in good condition. Check for wear, corrosion, or stripped threads before reusing.

3. Why do CF flanges use copper gaskets?

Copper gaskets create a perfect vacuum seal because they deform slightly when compressed, filling tiny gaps.

4. How do I prevent vacuum leaks when using CF flange bolts?

- Use clean, undamaged gaskets.

- Tighten bolts evenly in a crisscross pattern.

- Don’t over-tighten!

5. Can I use normal bolts instead of CF flange tapped bolts?

No. Regular bolts won’t provide the same level of vacuum sealing and might not fit properly.

Got any more questions? Drop them in the comments, and we’ll be happy to help!

Leave a Reply